Does the word ‘manufacturing’ invoke images of a dark, dirty factory with masses of people doing repetitive actions? Manufacturing of today, as the saying goes, “is not your grandfather’s manufacturing.” In the semiconductor industry, the saying has been adopted and changed to “ this not your grandfather’s semiconductor industry.” With the rapid pace of technology, the semiconductor industry of 50 years ago is dramatically different than today. To produce a semiconductor, equipment must be able to manufacture at sub-atomic levels in one of the cleanest environments in the world. To top it off, the yield, percentage of good chips, must be close to 99.9% to economically make sense. Semiconductor manufacturing is a dichotomy of innovation and control. It is where years of collaboration, R&D and experience come together to build the most complex devices that power everything we use to work, travel, communicate, and more.

Here are five facts about semiconductor manufacturing you will want to know:

A semiconductor starts with sand. Not just any sand, but silica sand with extremely high concentrations of quartz. The sand is purified to contain less than one in a billion non-silicon atoms. A small crystal seed is used to grow a single crystal silicon ingot or “boule” which is then sliced into silicon wafers.

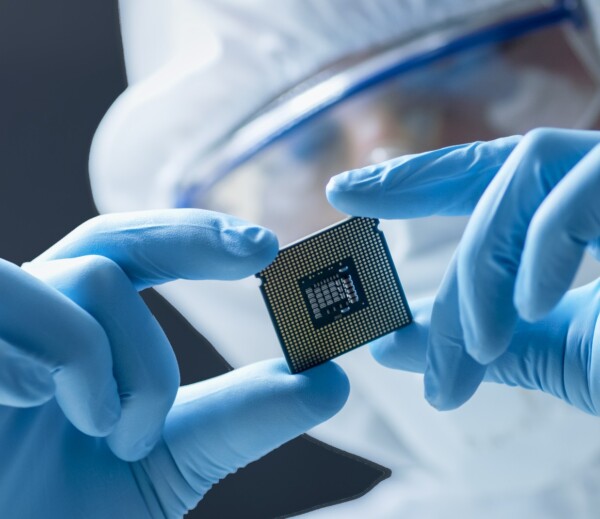

Semiconductors are among the smallest things humanity has ever dealt with. Cutting-edge semiconductor technology has dimensions down to 5 nanometers, 5 billionths of a meter (the average human hair is 100,000 nanometers wide).

On the average, there are approximately 500+ pieces of high-tech equipment needed in a fab. A single chip requires more than 700-1,000 steps and more than 60 days to manufacture.

A single speck of dust can cause millions of dollars. Semiconductors are so tiny that any particle can cause complete havoc and shutdown the entire chip-making process. To avoid this, semiconductor fabs are extremely clean, 100 – 1000 times cleaner than most surgery rooms in a hospital.

A single chip can have billions of electronic components such as transistors in less than a few square millimeters.

Does the word ‘manufacturing’ invoke images of a dark, dirty factory with masses of people doing repetitive actions? Manufacturing of today, as the saying goes, “is not your grandfather’s manufacturing.” In the semiconductor industry, the saying has been adopted and changed to “ this not your grandfather’s semiconductor industry.” With the rapid pace of technology, the semiconductor industry of 50 years ago is dramatically different than today. To produce a semiconductor, equipment must be able to manufacture at sub-atomic levels in one of the cleanest environments in the world. To top it off, the yield, percentage of good chips, must be close to 99.9% to economically make sense. Semiconductor manufacturing is a dichotomy of innovation and control. It is where years of collaboration, R&D and experience come together to build the most complex devices that power everything we use to work, travel, communicate, and more.

Here are five facts about semiconductor manufacturing you will want to know:

A semiconductor starts with sand. Not just any sand, but silica sand with extremely high concentrations of quartz. The sand is purified to contain less than one in a billion non-silicon atoms. A small crystal seed is used to grow a single crystal silicon ingot or “boule” which is then sliced into silicon wafers.

Semiconductors are among the smallest things humanity has ever dealt with. Cutting-edge semiconductor technology has dimensions down to 5 nanometers, 5 billionths of a meter (the average human hair is 100,000 nanometers wide).

On the average, there are approximately 500+ pieces of high-tech equipment needed in a fab. A single chip requires more than 700-1,000 steps and more than 60 days to manufacture.

A single speck of dust can cause millions of dollars. Semiconductors are so tiny that any particle can cause complete havoc and shutdown the entire chip-making process. To avoid this, semiconductor fabs are extremely clean, 100 – 1000 times cleaner than most surgery rooms in a hospital.

A single chip can have billions of electronic components such as transistors in less than a few square millimeters.